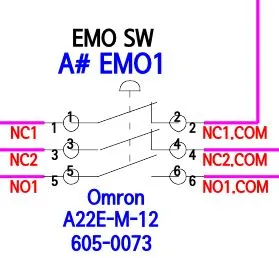

An EMO switch, sometimes called an emergency stop button, is a large, clearly marked control installed on machines. It enables operators to quickly cut power or stop operations in case of danger. Positioned in an easily accessible location, the EMO switch ensures that anyone nearby can intervene instantly when an emergency arises.

These switches are commonly red with a yellow background for high visibility and are designed to be easy to activate without confusion. Their mechanical design often includes a “latching” feature, which means once pressed, the machine remains stopped until the switch is manually reset, preventing accidental restarts.

Why is the EMO Switch Essential?

Firstly, the EMO switch is vital for protecting human life. In industrial settings, fast machine shutdown can prevent injuries, reduce accident severity, and in some cases, save lives. When a hazard or malfunction occurs, the EMO switch allows workers or supervisors to intervene immediately without relying on complex controls.

Secondly, the EMO switch prevents costly damage to expensive machinery and production lines. Uncontrolled machine operation can lead to equipment failure, product defects, or even fires. Using an EMO switch can reduce downtime and repair costs by stopping issues before they escalate.

Furthermore, industrial safety standards such as ISO 13850 and OSHA regulations mandate the use of emergency stop devices. Compliance not only ensures worker safety but also protects companies from legal liabilities and fines.

What Happens Without an EMO Switch?

Operating machinery without an EMO switch significantly increases risks. If a machine malfunctions or an unsafe condition arises, operators have no immediate method to stop the equipment. This delay can cause:

- Severe injuries or fatalities due to entanglement, crushing, or electrical hazards

- Extensive damage to machinery, which may require costly repairs or replacements

- Increased risk of fire or chemical spills depending on the equipment

- Production losses due to emergency shutdowns or accidents

- Legal consequences for failing to meet safety regulations

Moreover, the absence of an EMO switch can erode worker confidence in safety protocols, leading to decreased morale and productivity.

Best Practices for EMO Switch Implementation

To maximize safety, engineers should ensure the EMO switch is:

- Clearly visible and easily accessible at all operator stations

- Properly labeled and color-coded according to standards

- Regularly tested and maintained to ensure functionality

- Integrated with other safety systems like alarms and interlocks

- Installed according to the manufacturer’s guidelines and safety codes

Training all personnel on the importance and operation of the EMO switch is equally crucial to guarantee rapid response during emergencies.

Conclusion

In conclusion, the EMO switch is an indispensable safety feature in any industrial or engineering environment. It protects human lives, prevents equipment damage, and ensures compliance with legal requirements. Ignoring or omitting the EMO switch not only endangers workers but also jeopardizes operational continuity and legal standing.

Therefore, every engineer must prioritize the installation, maintenance, and correct use of EMO switches to safeguard people, machines, and business outcomes effectively.

Leave a Reply