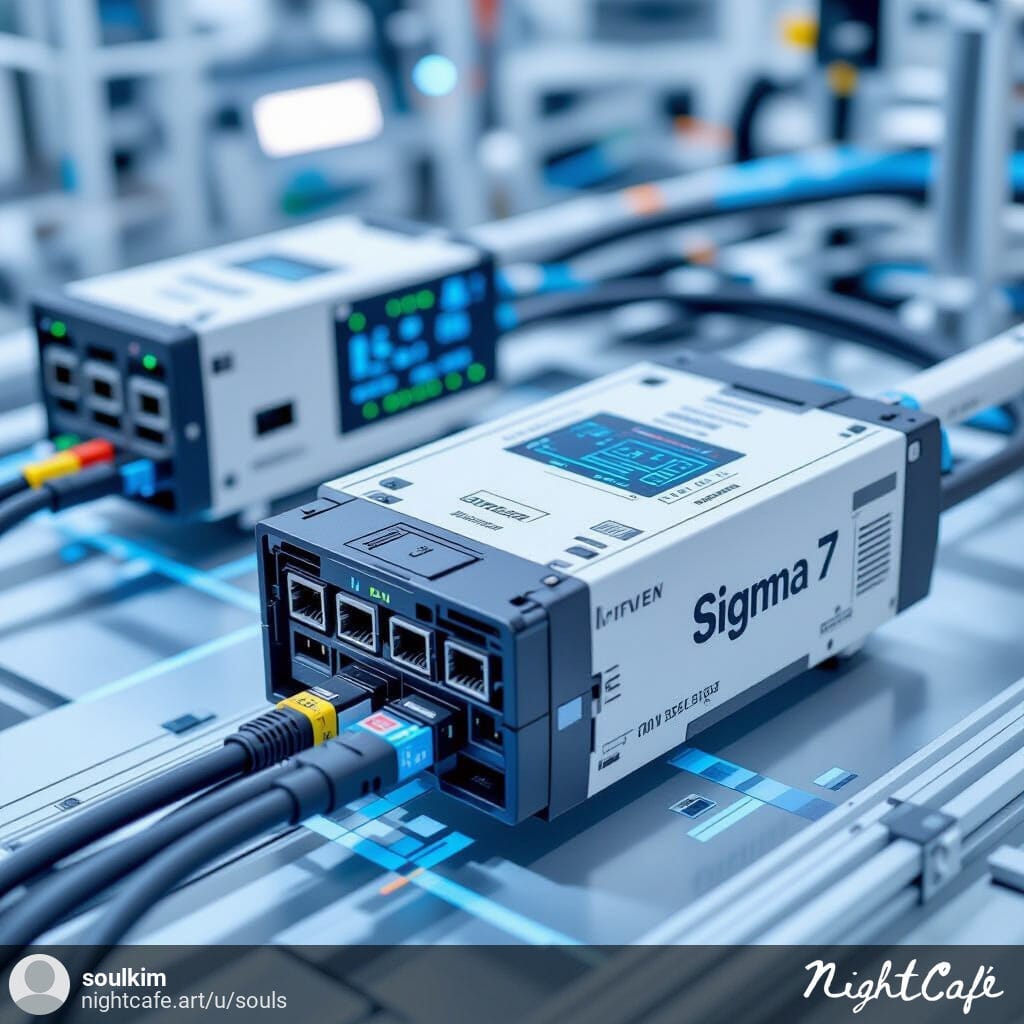

1. Overview of YASKAWA Sigma7

YASKAWA’s Sigma7 series is a next-generation servo system designed for high-speed, high-precision industrial motion control. It provides significant improvements in performance, efficiency, and reliability compared to the previous Sigma-5 lineup.

Sigma7 systems are widely used in applications such as semiconductor equipment, packaging machines, robotics, and CNC systems. The product family includes a wide range of servo drivers (SGD7 series) and compatible rotary or linear servo motors (SGM7 series), covering both low- and high-capacity motion demands.

Key Features of Sigma7:

- Ultra-high-speed current and velocity control loops

- Improved vibration suppression and real-time tuning

- Built-in safety functions (STO, SS1, etc.)

- Support for advanced communication protocols like MECHATROLINK-III and EtherCAT

- Compact size with increased power density

Sigma7 is ideal for systems requiring precise positioning, high acceleration, and seamless integration with modern control networks.

2. Introduction to Motor and Driver Components

A typical YASKAWA Sigma7 servo system consists of two main hardware components:

🔹 Servo Driver: SGD7 Series

The SGD7 series is the core of Sigma7’s control system. It receives control commands (from a PLC, PC, or controller), processes the motion profile, and drives the motor accordingly. Each driver includes:

- Power input terminals

- Motor output terminals

- Encoder interface

- Communication ports (EtherCAT, MECHATROLINK-III, RS-485, etc.)

- Safety I/O (e.g., STO)

Popular models include:

- SGD7S (Single-axis driver, standard)

- SGD7W (Dual-axis driver)

- SGD7R (Large-capacity driver)

The driver also supports auto-tuning and real-time diagnostics via the SigmaWin+ software.

🔸 Servo Motor: SGM7 Series

The SGM7 series motors are high-performance rotary servos equipped with 24-bit absolute encoders. They provide high torque density, smooth motion, and low cogging, making them ideal for demanding automation tasks.

Key specs include:

- Rated output: from 50W to 15kW

- Rated torque: 0.16 Nm to 95 Nm

- Maximum speed: up to 6000 RPM

- IP67 protection in standard configuration

- Brake and oil seal options available

Motors are connected to the driver via two main cables:

- Power cable (U/V/W)

- Encoder cable (feedback and communication)

Proper motor-driver pairing is essential to achieve optimal performance and reliability.

3. Types of Communication Methods and How to Choose the Right One

When you’re working with Yaskawa’s Sigma7 series, choosing the right communication method isn’t just a technical decision — it directly affects performance, compatibility, and even troubleshooting ease. Let’s break down the major communication methods and talk about when and why you’d want to use each one.

💡 1. MECHATROLINK-III

MECHATROLINK-III is Yaskawa’s native high-speed motion network. It’s fast (100 Mbps), synchronized, and works seamlessly with Yaskawa controllers.

When should you use it?

If you’re building a fully Yaskawa ecosystem — say with a Yaskawa motion controller like MP3000 or Σ-7 MP — this is your best bet. You’ll get tight integration, less wiring hassle, and robust synchronization between multiple axes. In short, if you’re aiming for high-performance motion control and you’re sticking with Yaskawa across the board, MECHATROLINK-III is a smart choice.

Pros:

- Native support in Yaskawa ecosystem

- Synchronized motion control

- High reliability

- Fast and precise

Cons:

- Limited to Yaskawa systems

- Less flexible with third-party devices

🔌 2. EtherCAT

EtherCAT is one of the most popular industrial networks today — and for good reason. It’s fast, flexible, and widely supported across many manufacturers.

When should you use it?

If your system includes non-Yaskawa components, or you’re using a third-party PLC like Beckhoff, Omron, or Siemens, EtherCAT offers great interoperability. It also supports distributed I/O and large-scale systems without sacrificing speed.

Pros:

- Extremely fast and efficient

- Widely supported

- Great for mixed-brand environments

- Scalable to many nodes

Cons:

- Requires more setup effort than MECHATROLINK

- Slightly more complex to debug without tools

🔄 3. RS-485 / Modbus

RS-485 with Modbus RTU is a classic and simple option. It’s slower than the other two but often enough for basic positioning or simple monitoring applications.

When should you use it?

If your control system is low-cost, or if you’re just logging data or sending basic motion commands from a PC or simple controller, RS-485 might be all you need. It’s especially useful in retrofits or small-scale applications.

Pros:

- Low-cost

- Easy to implement

- Works with most PLCs and HMIs

- Good for monitoring, simple control

Cons:

- Slow and non-deterministic

- No synchronization

- Not ideal for complex motion

🧭 So, How Do You Choose?

Here’s a simple way to think about it:

| Situation | Best Option |

|---|---|

| All-Yaskawa setup, high-performance motion | MECHATROLINK-III |

| Mixed-brand system, high-speed I/O | EtherCAT |

| Basic control, low cost, or retrofitting | RS-485 / Modbus |

If you’re building a new machine and performance is a priority, go with EtherCAT or MECHATROLINK. If you’re on a tight budget or working with legacy hardware, RS-485 gets the job done — just don’t expect sub-millisecond precision.

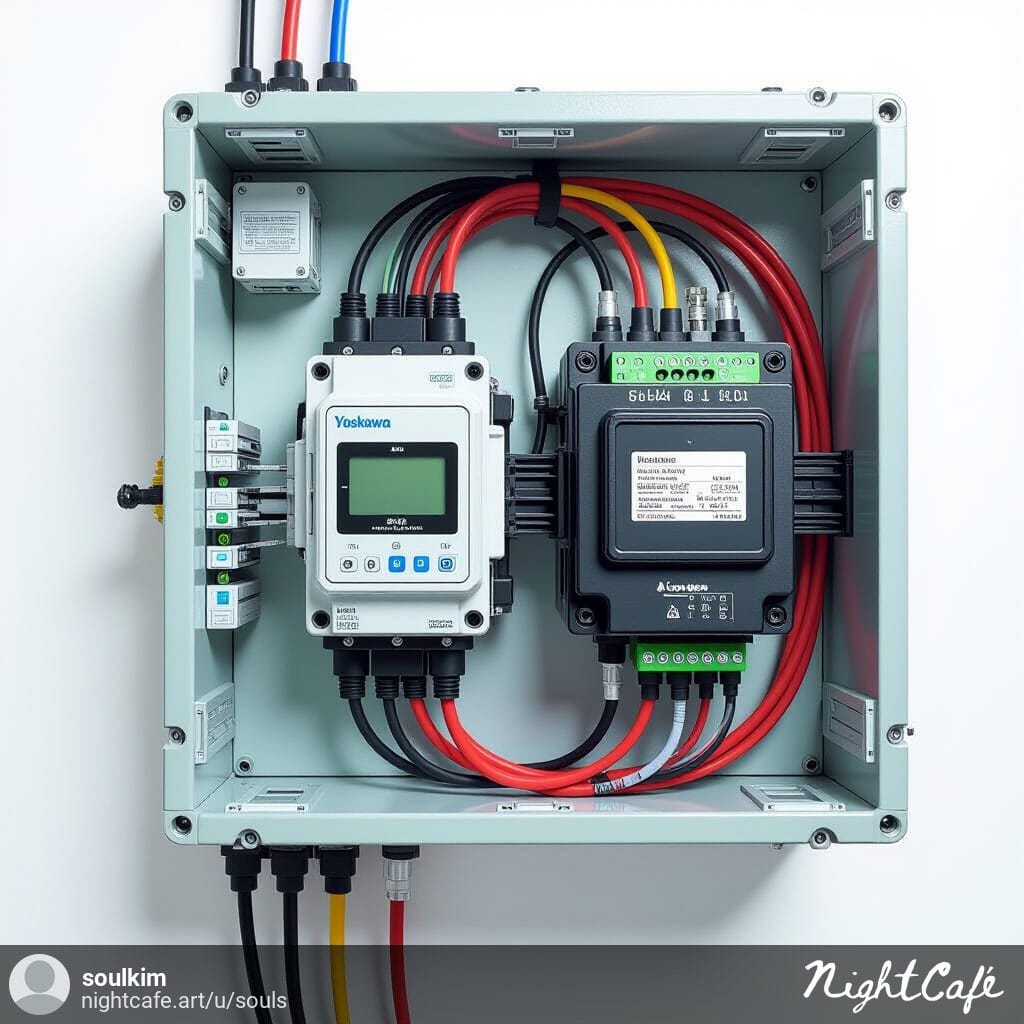

4. Hardware Connection Guide

Proper wiring and hardware setup are foundational for a stable Sigma7 system. Here’s how to connect the components:

🔌 Connecting the Motor and Driver

- Power cable (U, V, W): Connects motor to driver output terminals.

- Encoder cable: Connects motor feedback to the encoder port on the driver.

🧰 Additional Wiring

- Brake power (if used): Must be connected separately.

- Grounding: Proper grounding is critical for noise immunity.

- Shielded cables: Recommended for all communication and encoder lines.

🔗 Communication Cabling

Depending on the protocol used:

- MECHATROLINK-III: Use Yaskawa-certified shielded twisted pair cables (RJ-45).

- EtherCAT: Standard CAT5e/6 with industrial connectors (M12 or RJ-45).

- RS-485: Twisted pair with termination resistors on both ends.

Cable routing should minimize EMI by keeping power and signal lines apart and using proper shielding.

5. Parameter Configuration Guide

Before powering up the system, key parameters must be set to match your motor, load, and communication protocol.

🛠 Basic Startup

- Factory reset (optional)

- Motor model auto-detection or manual setting (Pn002)

- Load inertia adjustment (Pn103)

🖧 Communication Parameters

- Pn002.1: Control method (pulse, MECHATROLINK, EtherCAT, etc.)

- Pn212 – Pn216: Node address, baud rate, etc.

- Pn001 – Pn005: Motor constants

💻 SigmaWin+ Software

Yaskawa’s configuration software, SigmaWin+, enables:

- Parameter editing

- Monitoring and waveform analysis

- Alarm history review

- Real-time tuning and diagnostics

Make sure to save parameter backups regularly.

6. Communication Setup with Motion Controllers

Once parameters are configured, you’ll need to establish communication between the Sigma7 driver and your controller.

🔧 With a PLC or PC

- Ensure matching settings (e.g., node address, baud rate)

- For EtherCAT, use a master controller with XML ESI file support

- For Modbus/RS-485, configure correct slave ID and register mapping

📦 Configuration Details

- Assign PDO mappings (EtherCAT)

- Define I/O areas and cyclic update intervals

- Use SigmaWin+ or your PLC’s configuration software for integration

Reliable communication ensures stable operation and reduces fault risk.

7. Basic Motion Testing

With hardware connected and communication established, it’s time to verify system functionality.

▶ Jog Test (Manual Move)

Using SigmaWin+:

- Enable servo (SV_ON)

- Use jog buttons to move motor

- Observe encoder feedback and torque

🚨 Alarm and Error Monitoring

- Check display panel (LED codes)

- Use SigmaWin+ for detailed alarm logs

- Common issues include overcurrent, encoder errors, or communication faults

Successful jog testing confirms proper installation and readiness for integration.

8. Common Issues and Troubleshooting Tips

Even with a correct setup, issues can occur. Here are common problems and how to fix them:

| Problem | Possible Cause | Solution |

|---|---|---|

| No communication | Incorrect cabling or parameters | Check wiring and communication settings |

| Servo not turning | Not enabled, or alarm present | Clear alarms and activate SV_ON |

| Alarm code “A.C0”, “A.91”, etc. | Overload, encoder fault, or wiring | Refer to manual and check motor load |

| Vibration or noise during motion | Tuning not optimized | Use real-time tuning via SigmaWin+ |

Maintaining a clean power environment and properly shielding cables can eliminate 80% of common issues.

9. Practical Tips and Resources

To wrap up, here are some helpful suggestions for field engineers:

🔧 Setup Tips

- Always use pre-made Yaskawa cables if possible

- Secure all connectors tightly to avoid vibration issues

- Label cables for easier maintenance

Leave a Reply