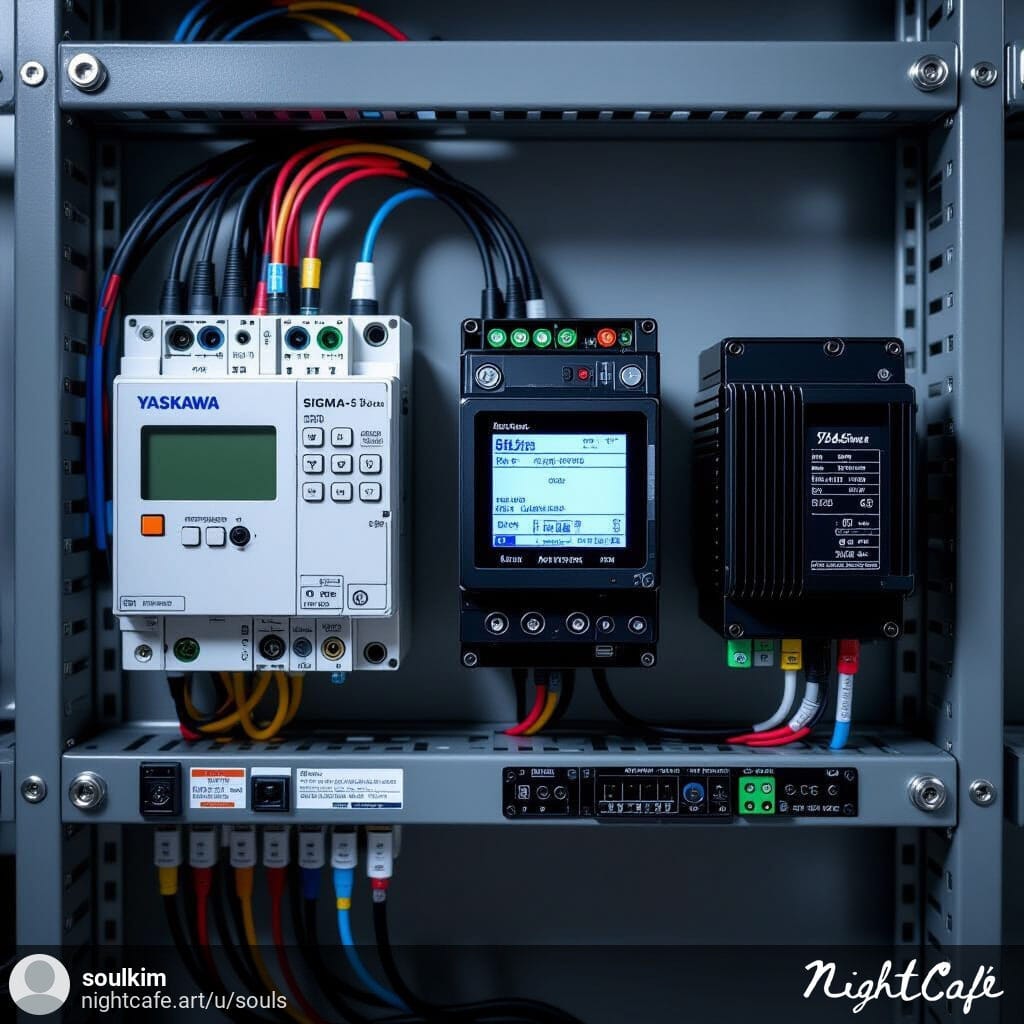

How to Connect Yaskawa Driver Motor via RS-485 Module

If you’re working with Yaskawa’s SIGMA-5 series, especially the SGDV-1R6AE driver, and need to set up communication using an RS-485 module, you’re in the right place. Today, I’ll walk you through the entire process, from understanding the key components to wiring, configuring parameters, and troubleshooting common issues. By the end, you’ll have a solid grasp of how to connect your Yaskawa servo driver and motor via RS-485 communication, making your automation project run smoothly.

Understanding Yaskawa SIGMA-5 and RS-485 Communication

Before diving into connections, let’s clarify what we’re dealing with. The SIGMA-5 series is Yaskawa’s high-performance servo system line. The SGDV-1R6AE model is a servo driver designed for medium to low power motors, typically in the 200 to 400-watt range. These drivers control precision motors that operate in manufacturing lines, robotics, or semiconductor equipment.

Now, RS-485 is a popular communication standard used in industrial automation. It supports multi-point communication on a single twisted pair cable and offers robust noise immunity, which is vital in noisy factory environments. When you combine the SIGMA-5 driver with an RS-485 module, you enable the driver to communicate efficiently with a PLC, HMI, or other control devices over a reliable serial link.

Key Components You’ll Need

To make this connection happen, you need three main components:

- SGDV-1R6AE Servo Driver – This is the heart of your system. It powers and controls the motor.

- Compatible Servo Motor – Usually, a SIGMA-5 motor like the SGMJV-02ADA6C or similar, matched to the driver’s specs.

- RS-485 Index Module and Index Module Case – This module acts as the communication bridge between the driver and your control system over RS-485. The case is the housing where the module securely fits and connects.

Step 1: Choosing the Right Motor for SGDV-1R6AE

Picking the right motor is crucial. The SGDV-1R6AE supports motors up to roughly 400 watts, so you’ll want to select one within that power range. For example, the SGMJV-02ADA6C is a great 200W motor with a 20-bit encoder that ensures precision positioning. Always check the motor’s rated current and torque to match it with the driver’s capacity.

Remember, using a motor outside the driver’s specs can cause overheating, poor performance, or even damage.

Step 2: Understanding the RS-485 Index Module

The RS-485 index module serves as a communication interface. It converts signals between the servo driver and your RS-485 bus, allowing multiple devices to talk on the same line without interference.

The Index Module Case is just the housing that holds and protects this module, often mounted on DIN rails for neat installation.

When you set this up, the Index Module enables you to monitor the driver’s status, send commands, and read feedback signals like motor position or alarms.

Step 3: Physical Wiring and Connections

Now, let’s talk wiring — the part where many engineers get stuck if they’re not careful.

- Power and Motor Cables: Connect your motor power cables (U, V, W) to the driver as per the manual. Also, connect the encoder cables correctly — the SIGMA-5 motors use a 20-bit absolute encoder, so the encoder connection is critical for accurate control.

- RS-485 Communication Lines: The RS-485 lines usually have A (+), B (−), and GND. You must connect these twisted pairs between the Index Module and your control system, like a PLC or industrial PC.

- Terminating Resistors: RS-485 networks require termination resistors at both ends of the communication line to prevent signal reflections. Check if the Index Module has built-in termination switches; if not, add 120Ω resistors manually.

- Power for Index Module: The Index Module might require a separate 24V power supply. Make sure you supply it according to the specifications.

Double-check all connectors and make sure cables are secure. Loose wiring often causes intermittent errors.

Step 4: Configuring Communication Parameters

Once the physical setup is done, configure the communication parameters on the driver and Index Module. This step ensures that both devices “speak” the same language.

Important settings include:

- Baud Rate: Common speeds are 9600, 19200, or 115200 bps. Match this setting on both ends.

- Node Address: Each device on the RS-485 bus needs a unique address. Assign addresses carefully to avoid conflicts.

- Parity and Stop Bits: Usually, 8 data bits, no parity, and 1 stop bit work well, but confirm your control system’s requirements.

- Timeouts and Retries: Set appropriate communication timeouts and retry counts to maintain stable links.

You configure these using the driver’s parameter settings (usually via software or built-in keypad) and your PLC or HMI configuration tools.

Step 5: Testing the Communication

With wiring and configuration complete, it’s time to test the link.

- Use diagnostic tools or your control software to send simple commands and verify the driver responds.

- Check for alarms or errors on the driver’s display.

- Monitor real-time data such as motor position, speed, and torque feedback.

- Confirm that commands like start, stop, and speed adjustments work smoothly.

If communication fails, re-check wiring, addresses, and baud rate settings.

Step 6: Troubleshooting Common Issues

Even with careful setup, problems can arise. Here are some common issues and how to fix them:

- No Response from Driver: Check RS-485 wiring polarity (A and B swapped is a common error). Also, verify power to the Index Module.

- Intermittent Communication: Look for loose connections, noisy cables, or missing termination resistors.

- Wrong Motor Behavior: Confirm encoder wiring and driver parameters match the motor specs.

- Address Conflicts: Make sure no two devices share the same node address on the RS-485 bus.

- Parameter Mismatch: Sync communication settings (baud rate, parity) between all devices.

Final Thoughts

Connecting a Yaskawa SGDV-1R6AE driver to its compatible motor through an RS-485 Index Module might seem complex at first, but breaking down each step makes it manageable. Careful wiring, proper parameter setup, and thorough testing will save you from downtime later.

In my experience, investing time upfront to understand the communication architecture and motor-driver compatibility pays off handsomely. Once configured properly, the SIGMA-5 system offers precise control and reliable performance that many industries rely on.

If you want, I can share sample wiring diagrams, parameter lists, or troubleshooting checklists next. Just let me know!

IF YOU WANNA TO KNOW : HOW TO DO YASKAWA DRIVER(SIGMA5) ERROR CODE(CLICK HERE)

Leave a Reply