Introduction to LS Motor Controllers

LS Electric, formerly LG Industrial Systems, is a leading global manufacturer specializing in industrial electrical equipment and automation solutions. Among its broad product portfolio, LS Motor Controllers stand out as essential devices designed to manage and protect electric motors across various industrial sectors.

Motor controllers from LS Electric provide reliable start, stop, and protection functions for motors, ensuring operational safety and efficiency. These controllers are engineered to meet the rigorous demands of modern industrial automation environments, adhering to international standards such as IEC and UL.

With the increasing complexity of automated systems, LS Motor Controllers have evolved from simple electromechanical devices to intelligent control units capable of integrating with advanced automation networks. This evolution enables real-time monitoring, fault diagnostics, and remote control, aligning with Industry 4.0 initiatives.

In this comprehensive guide, we will explore the different types, technical specifications, communication capabilities, and practical applications of LS Motor Controllers, equipping engineers and technicians with the knowledge necessary for optimal motor management in industrial settings.

Types of LS Motor Controllers

When it comes to LS Motor Controllers, there’s actually a variety of types you’ll want to know about. Each one serves a different purpose depending on what your motor needs and the environment it’s working in.

First off, we have Magnetic Contactors. These are basically switches that control the power to your motor. They’re super reliable and can handle frequent on-off operations, which makes them perfect for industrial settings where motors start and stop all the time.

Next up are Thermal Overload Relays. Think of these as your motor’s safety net. If your motor draws too much current for too long, these relays will kick in and cut the power to prevent overheating — protecting your motor from serious damage.

Then there are Manual Motor Starters. These combine the contactor and overload relay into one simple unit. They’re handy when you want to manually control the motor but still want built-in protection, especially useful for smaller motors or less complex systems.

Finally, LS offers Smart and Intelligent Motor Controllers. These are a bit more advanced — they not only protect your motor but also let you monitor and control it remotely through communication networks. With Industry 4.0 becoming the norm, these smart controllers are a great fit for modern factories aiming for automation and real-time data.

So, depending on your needs — whether it’s basic on/off control or full-fledged intelligent management — LS Electric has a motor controller that fits the bill.

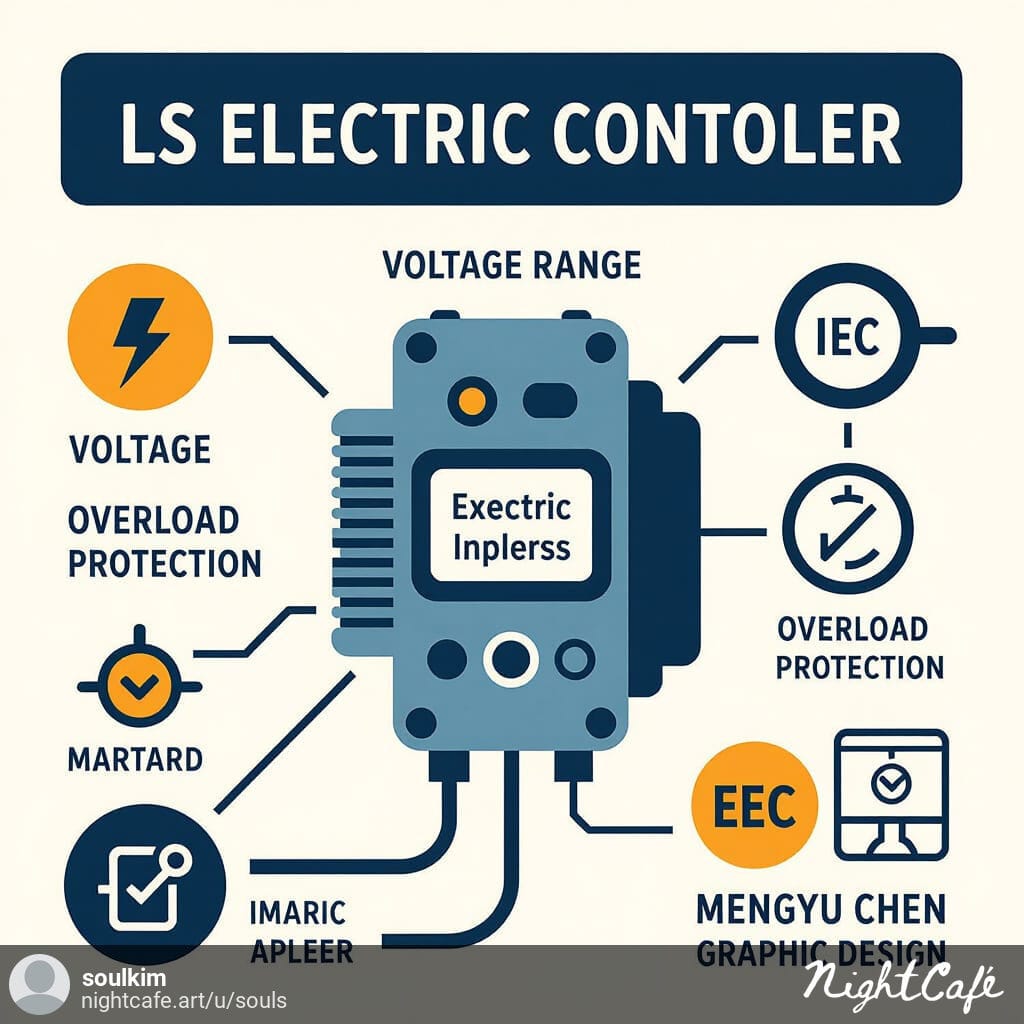

Key Features and Specifications

Now, let’s talk about what really makes LS Motor Controllers stand out — their features and specs. Understanding these will help you pick the right controller for your setup.

First off, LS controllers come with a wide range of voltage and current ratings. Whether you’re dealing with small motors or heavy-duty industrial machines, there’s a model that fits the bill. This flexibility is a big plus because you don’t want to over-spec or under-spec your controller.

Another important point is the protection functions. LS controllers aren’t just about switching motors on and off; they actively protect them. Think overload protection, short circuit detection, phase failure, and even ground fault monitoring. These features are designed to keep your motors safe and extend their life.

Also, you can’t overlook compliance with international standards like IEC and UL. This means LS controllers meet strict safety and performance benchmarks, which is reassuring if you’re working in regulated industries or exporting equipment globally.

What’s more, many LS controllers offer easy installation and configuration, plus some come with digital displays or communication ports that make monitoring a breeze.

So, all in all, LS Motor Controllers are built with reliability, safety, and user convenience in mind — exactly what you need on the factory floor.

Applications in Industrial Settings

So, where exactly do LS Motor Controllers get used? Honestly, their applications are pretty broad, covering a lot of industrial setups you’re probably familiar with.

For starters, they’re widely used in conveyor systems — those belts that move products around factories. Precise motor control is crucial here to keep things running smoothly and avoid jams.

They’re also common in fans and pumps, where controlling motor speed and protecting against overloads helps improve energy efficiency and equipment lifespan. You’ll find these in HVAC systems, water treatment plants, and more.

Another big area is compressors and other heavy machinery. LS controllers handle the tough demands of these motors, ensuring they start safely and stay protected against faults.

What’s more, with the rise of smart factories, LS Motor Controllers fit right in with energy monitoring and load management systems. By integrating with networked control systems, they help optimize power usage and reduce downtime.

In short, whether it’s simple machinery or part of a complex automated system, LS Motor Controllers play a vital role across many industrial environments.

Installation and Wiring Guidelines

Now, let’s talk about getting those LS Motor Controllers set up properly. Installation might seem straightforward, but a few tips can really save you headaches down the line.

First, always pay close attention to the terminal layout. LS controllers come with clearly labeled terminals, but double-checking the wiring diagram before you start is a must. Miswiring can lead to malfunction or even damage.

When mounting the controller inside your control panel, make sure there’s enough space for ventilation and easy access. Also, arrange the wiring neatly — this not only looks professional but helps with troubleshooting later.

Grounding is another critical point. Proper grounding reduces electrical noise and prevents interference that could mess with your controller’s operation. Don’t skip on good grounding practices.

Also, keep an eye on EMI (Electromagnetic Interference) issues. Use shielded cables where necessary and separate power wiring from control wiring as much as possible.

By following these guidelines, you’ll ensure that your LS Motor Controller runs smoothly and reliably from day one.

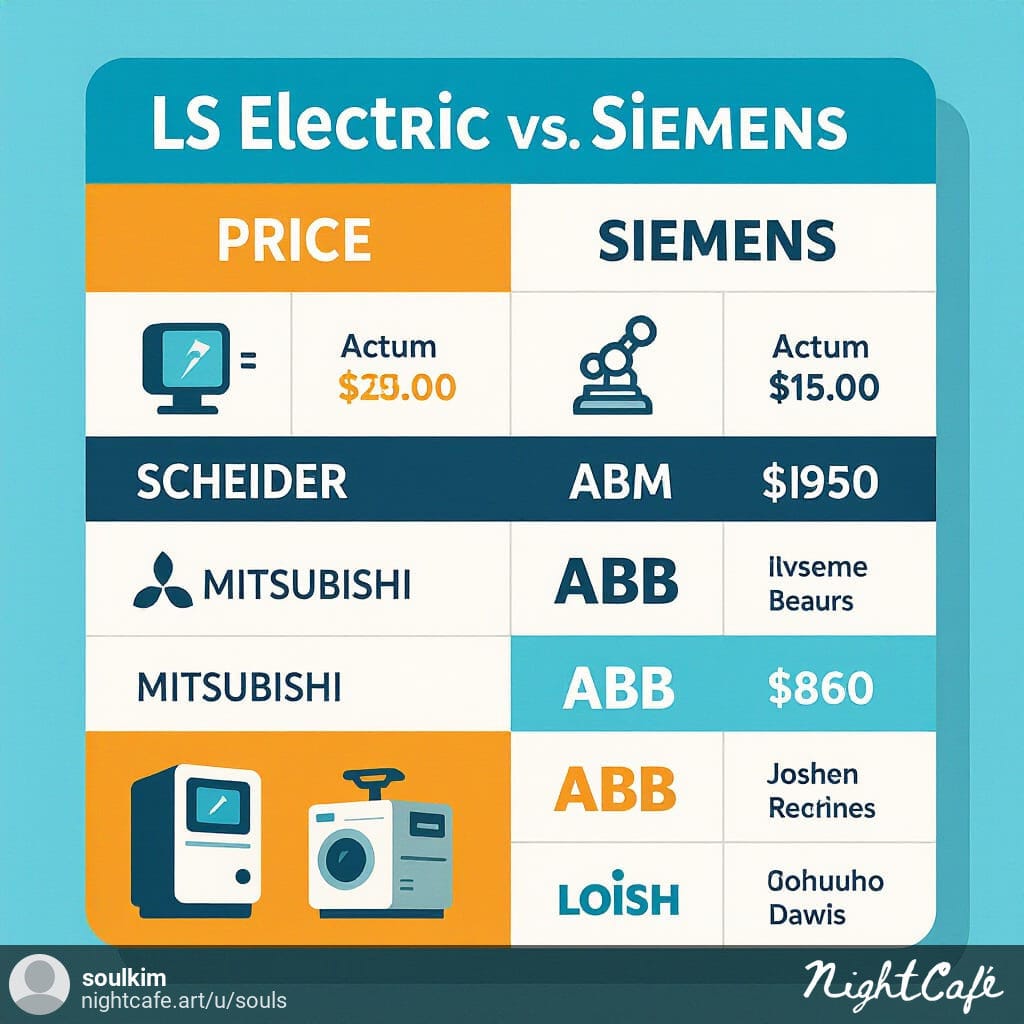

Comparison with Other Brands

When choosing motor controllers, you might wonder how LS stacks up against the big names like Siemens, Schneider, Mitsubishi, or ABB. Let’s break it down.

First, LS Electric generally offers competitive pricing without compromising quality. So if you’re watching your budget but still need reliable gear, LS is definitely worth considering.

In terms of functionality, LS controllers cover all the basics — plus some smart features like communication support and advanced protections. While Siemens or Schneider might have a few more bells and whistles, LS hits the sweet spot for most industrial applications.

Support and availability also matter. LS has a strong presence, especially in Asia, and good local support networks. Depending on your region, this can be a huge advantage for getting parts quickly or technical help.

Overall, if you compare specs and cost, LS Motor Controllers offer excellent value, balancing performance and price — making them a smart choice for many engineers and technicians.

Troubleshooting and Preventive Maintenance

Let’s be honest — no matter how good your motor controller is, sometimes things go wrong. But the good news with LS Motor Controllers is that troubleshooting and maintenance are pretty straightforward.

First off, many LS controllers come with diagnostic LEDs or digital displays. These indicators quickly tell you what’s up — whether it’s an overload, short circuit, or phase failure. So, before diving deep, check those lights; they often point you straight to the problem.

If something trips, a simple reset procedure usually gets things back on track. Just make sure you identify and fix the root cause first, so the issue doesn’t keep recurring.

Preventive maintenance is just as important. Scheduling regular inspections to check wiring tightness, cleaning dust from terminals, and testing protection functions can save you from unexpected downtime.

In short, with a bit of regular care and paying attention to diagnostic cues, LS Motor Controllers can keep running smoothly for years.

Where to Buy and Accessing Technical Support

So, if you’re ready to get your hands on an LS Motor Controller, where should you start?

First, LS Electric products are widely available through authorized dealers and OEM partners. Buying from these official channels ensures you get genuine products with warranty and reliable support.

You can also find datasheets, manuals, and firmware updates on LS Electric’s official website. These resources are super helpful for installation, configuration, and troubleshooting.

If you run into any issues or need technical advice, LS offers professional support through their regional offices and partners. Don’t hesitate to reach out — having expert help can save you a lot of time and hassle.

In short, sticking to authorized sources and using available technical resources will make your experience with LS Motor Controllers much smoother.

Conclusion and Professional Insight

To wrap things up, LS Motor Controllers really stand out as solid, reliable solutions for motor management in industrial settings. Whether you need a basic controller for simple on/off control or a smart device that integrates seamlessly with your automation network, LS has you covered.

From my experience and feedback from fellow engineers, LS strikes a great balance between cost, performance, and ease of use. Plus, their communication features make them a smart choice for anyone moving toward Industry 4.0 and smart factory setups.

Of course, no product is perfect, so always make sure to choose the right type and specs for your specific application. But overall, LS Motor Controllers offer dependable protection and flexibility that keep your motors running smoothly and your operations efficient.

If you’re looking for a practical, well-supported motor control solution, LS Electric should definitely be on your shortlist.

Leave a Reply